It enables you to process materials such as wood, composite, plastic, aluminum with high quality and speed. The features of the spindle motor used can be optionally selected according to the hardware features of the machine you have requested.

During surface treatment, it automatically contacts the treated surface with the help of pistons and ensures efficient dust extraction.

It allows the operator to control the machine independently from the control panel.

Tool length measuring unit is used to minimize the pre-process preparation time. Automatic tool measurement saves the reference in its memory. Thus, it ensures that we can obtain healthy results in every transaction.

With the automatic tool changing unit, you can get faster measurements by saving time and more practice. In line with the hardware features of the machine you have requested, a machine with a capacity of 8 sets is also available.

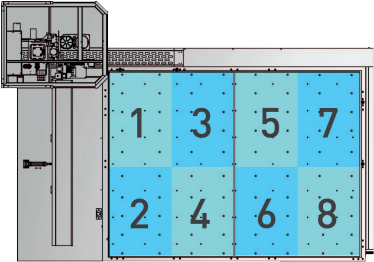

The machine table is made of Flat Table (POM) material. In order for vacuuming to be efficient, it is divided into 6 or 8 equal vacuum zones according to the size of the desired machine. These areas on the table can be controlled independently to provide a stronger grip in the working areas. According to the hardware features of the machine, the areas used can be activated from the control panel or with the help of a manual valve, and the unused areas can be closed.

High-quality linear slides and ground helical racks are used with maximum precision to ensure efficient axial movements at high speeds. It has been designed to achieve quality results in the work done.

It minimizes reference misalignment in the materials to be processed.

The machine work table can be used in multi-zone logic with optionally increasing vacuum zones. Vacuum zones can be controlled independently by the control unit and provide maximum grip during processing of small parts, helping to make the most efficient use of vacuum capacity.