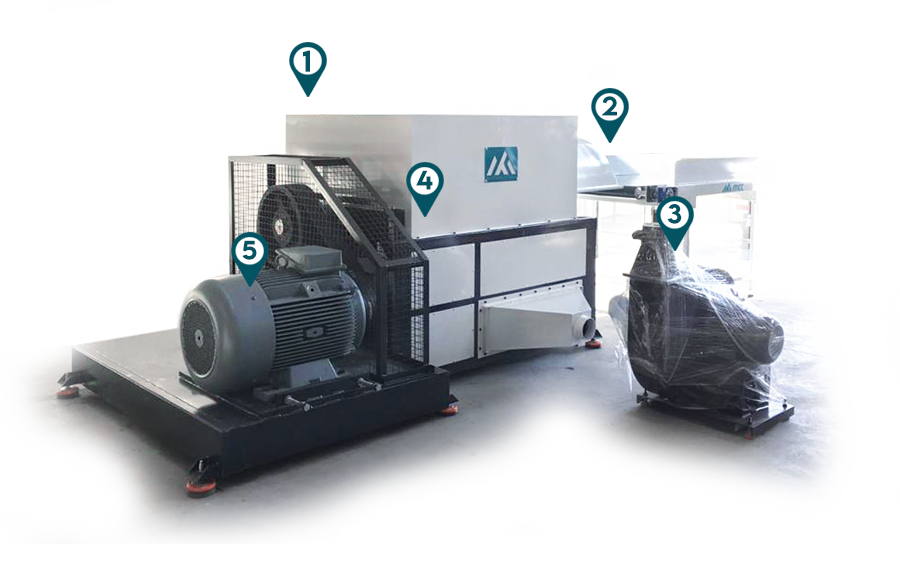

Thanks to the harmonious design of the drum, motor and sieve system, the daily capacity is 4-5 tons of sponge.

It enables the operator to load products from a safer area outside the machine working area in order to prevent work accidents that may occur.

It ensures that the clipped sponges are discharged from the machine chamber with the fan.

High quality clippings are obtained thanks to the precise measurement and the nail system made of special steel in harmony with each other.

It enables the machine to work comfortably, efficiently and with low power consumption in the sponge clipping process.